Microsoft Fabric & Manufacturing: Turning Data into Your Greatest Asset

Manufacturers have been told data is the new oil. The reality often feels more like data is the new headache. Microsoft Fabric aims to change that.

For decades, manufacturing success was about physical assets: machines, materials, logistics. Data existed, but it was a byproduct – buried in spreadsheets, siloed in departmental systems, and largely ignored except for compliance reporting.

That's changing.

Sound familiar?

Today, the most competitive manufacturers treat data as a strategic asset in its own right. They use it to predict equipment failures, optimise production schedules, reduce waste, and respond faster to changing demand. The challenge is that manufacturing data is messy, scattered, and hard to unify.

Microsoft Fabric is one of the platforms designed to address this.

What Fabric actually is

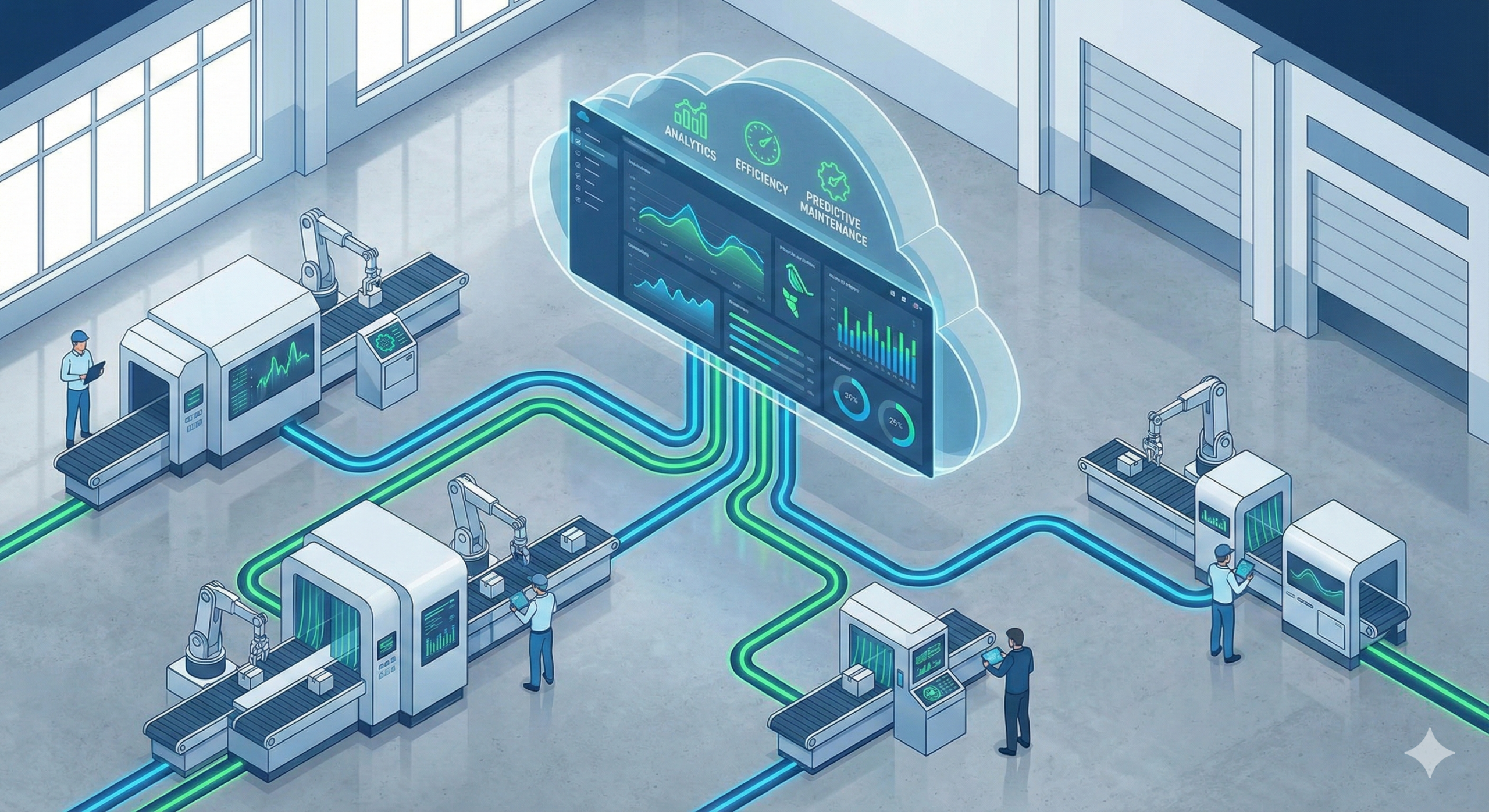

Fabric is Microsoft's unified analytics platform, combining data engineering, data integration, data warehousing, real-time analytics, and business intelligence in a single environment. For manufacturers, the appeal is the ability to bring together data from PLCs (programmable logic controllers), SCADA (supervisory control and data acquisition) systems, MES (manufacturing execution systems), ERP (enterprise resource planning), and quality systems into one place – without building a custom data warehouse from scratch.

Why this matters for manufacturing

The promise is a "single source of truth" for operational and business data, accessible to analysts, engineers, and decision-makers across the organisation.

In practice, this means:

- Connecting shop floor to top floor. Real-time production data can feed dashboards that executives actually use, not just reports that arrive weeks later.

- Enabling predictive maintenance. With unified data, machine learning models can identify patterns that predict failures before they happen, reducing downtime and maintenance costs.

- Supporting quality and compliance. Traceability becomes easier when all relevant data lives in one system, reducing audit pain and recall risk.

- Improving demand responsiveness. When sales, inventory, and production data are integrated, you can adjust schedules faster and avoid both stockouts and overproduction.

Getting started

None of this happens automatically. Fabric is a platform, not a solution. You still need to define what questions you want to answer, clean and map your data sources, and build the reports and models that deliver value.

For many manufacturers, the starting point is a pilot focused on one high-value use case – often OEE (overall equipment effectiveness) visibility or predictive maintenance for a critical asset. Success there builds confidence and justifies further investment.

The people aspect

It's also worth noting that technology is only part of the equation. Data culture matters. If shop floor teams don't trust the numbers, or if managers continue to rely on gut feel, the investment won't pay off. Change management, training, and visible leadership support are essential.

The bottom line

Microsoft Fabric isn't the only option – other platforms exist, and some manufacturers build bespoke solutions. But for organisations already invested in the Microsoft ecosystem, Fabric offers a relatively low-friction path to unified analytics.

The real question isn't which platform to choose. It's whether you're ready to treat data as a core asset, not an afterthought.

If you'd like help building a data strategy for your manufacturing operation, get in touch.

Martin Sandhu

AI Product Consultant

I help founders and established businesses build products that work. 20+ years in product and engineering.

Connect on LinkedIn